WATER TREATMENT

What is water

Water is the combination of two molecule of

hydrogen and one molecule of oxygen.

2H2+O → H2O

In a thermal power plant main sources

is water so it can must be required

to plenty amount for produced electricity through steam flowing to steam

turbine.

So that the raw water is carried

out from river ,sea , kennel etc. This

raw water contain some impurities to remove those impurity water treatment

plant must be required.(the impurity

are salt and mineral, Organic material,

Biological ,Oil and grease, Floating solid, Colloids, Colour , Order, Suspended

solids etc).

Process of making DM water from

raw water in WTP

In

water treatment plant raw water is carried out from river,lakes,sea etc.These

raw water contains impurity like large material

which is removed through mesh,The process of removed large particle

material is called Screening.

After screening the raw

water is storage a large sourrounded area where remove some bacteria by

mixing of chlorine in water in ths

process is called Areation.

After aeration process

complete we get a clarify water through clarification by filter is called

Pre-treatment of WTP. It involves Coagulation, Floculation after that clarifier

used to remove sludge in water through pressure filter.

After clarification active

carbon filter is used as a filter bed

through which water is passed .it main function is to activate carbon by

oxidation of water by free of chlorine .in active carbon filter a membrane filter is used to removed non-reactive

silica.

After removing silica through

active carbon filter we make DM water by post-treatment through Anion exchange

resin, Cation exchange resin, Mix bed unit ,after cat ion exchange the influent acid and all

the bicarbonate present in water which convert CO2 .This CO2 is removed through

degasser through degasser pimp otherwise co2 is removed in anion exchange

method .and De-Mineralised water is prepare to formation of Steam.

Why DM water is used formation of steam not in raw water

Because DM water does not contain any

impurities which is suitable for produced steam. If we use raw water it contain

impurities like silica when the raw water is feed to boiler the silica is

deposited on boiler water wall tube which reduced heat transfer and silica

deposited inner surface of tube which occurred Scaling.

Method of treatment of

water in WTP

Two type of method

used in water treatment plant

1> Pre-Treatment

This method is used to avoid

corrosion in boiler tube

silica, colloids, suspended solids,

organic mater, bacteria,

physically mixed, floating solid etc

removed in pre treatment plant

2>Post-treatment

Post treatment is used to remove

dissolve gasses and solid to make DM water

1-PRE-TREATMENTPLANT

|

Pre treatment is used to remove suspended solids, colloids, organic matter etc. Process of removing those things steps are below given.

Ø Screening

Screening is provide to avoid large size

floating material comes from with water from river.the screening are 25mm dia

hole and are spaces about 100mm apart and placed slightly inclination from

vertically which is easy to remove large particle,here velocity of water should

not exceed 0.5m/s. After screening a fine screen fitted through orifice in size

of 6mm dia to removeparticle in size of 6mm dia to remove particle are also

called travelling water screens.

Ø Raw water storage

After screen the raw material is storage

large surrounded area at 7 to 15 days

for improvement of water quality and average water demand and also reduced bacteria, suspended solids and river algae etc.

Ø Prechlorination

This process chlorine

is injected into raw water for destroys the high bacteria ,oxidizes, iron and

manganese are kill algae ,reduces colour etc.

Ø Aeration

The process is used to controlling taste,

order, and Corrosion but not all case complete control gases are absorbed or

liberated from water between natural gas contain in atmosphere and gas contain

in water , the volatile matter and decomposing organic matter can be manganese

in solution are also oxidized and precipitated out.

Ø Coagulation

This process small

particle suspension together to from large agglomerate. Fine particles and

colloids are present in water which carry negative charges on their surface

which are true coagulation into a large particle which depend upon frequency of

collision. So it is very important process to accelerate sedimentation of

suspended particles coagulation aids is

different type which are all long chain molecules carrying electrically active

group like long chain poly acrylic amides which carries positive charges.

Ø Flocculation

When ferric and aluminium

salts added into water is formed insoluble hydroxide which comes out as flocks

whose surface carry positive flocks attracts itself with the negative charged

particles in water and also attracts and holds humic acid. When alums added in

water aluminium hydroxide floc and sulphuric acid is reduced PH value of water

normally raw water PH is alkaline, after addition of alum in water PH value may

be down to coagulation pit. In rainy season when turbidity is high , alum

dosing is high in that case PH may faill below coagulation PH. So Lime ca(OH2) is

used to increase PH to required level & helps to remove some hardness.

Ø Clarifiers

This system which water is cleared form most

of the suspended solids with or without coagulation then there is different types

of clarifiers.

1>Conventional type

2>Hopper to remove sludge - it is used to remove sludge

Ø Filteration

Filtration means removing suspended solid out

of fluids and colloids from water. in case of filtration no sands and mud are

not filtration here water which has been

screened and settled which contained

suspended matter and colloids .colloids are those particles which does not show

in microscope which size is 0.005 to 0.2 microns in diameter. The colloids is

water absorb and scatter light passing through it this process remove suspended

solids in water.

1>Deep

bed filter

It

is used to removed sand always back washed

upward and san bed expand and solids are released

It is 2 type

-Up flow filter

-Down flow

filter

2>Slow and rapid sand filter

Its flow is 1-2kg /sqft/hr and

100litr/sq-m/hr

3>Activated

carbon filter

It is used to remove bacteria growth it main function is oxidisation of

water by free chlorine.

4>Membrane filter

A Ultra filtration membranes used to remove

non-reactive silica with a pressure of 5 bar water have total dissolve salts or

more than 500 ppm.

2 POST TREATMENT

Post treatment is used in DM plant

maded ehich is 3 type of process.

a) Ion exchange method

b)chemical softonic method

c)Reverse osmosis method

Ø ION EXCHANGE METHOD

In this method includes anion exchange resin and cation exchange reign for removing dissolve solid

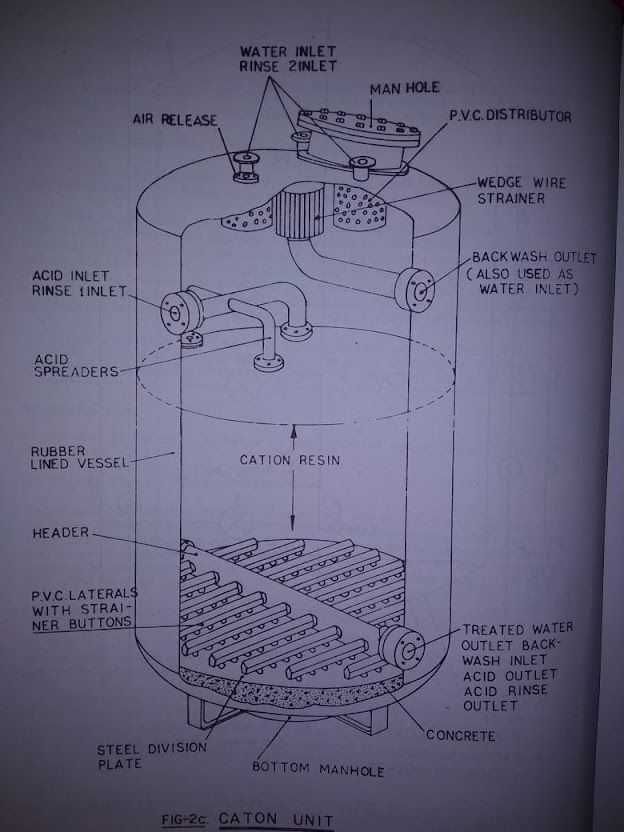

Cat ion exchange method

Cat

ion is positive charge but in acid which represent H+ and its resin is R+ it is two type

1. Strong acid cation exchange

When the function group

attached to resin matrix is strong acid

group is called SAC resin. It split all salts and influence by PH of water its operational exchange capacity

and regeneration efficiency of SAC is less than WAC.

2.Weak acid cation exchange

When the

functional group is of weak acid is called WAC resin it can spited weak

electrolyte carbonate and bicarbonate only.

Anion exchange method

It can denoted

OH- and negative charge it is two

type

1.Strong base anion resin

Strong Based anion the functional group is strong base is called

SBA.it

performance is not influenced by water PH

and it exchange with both strong and weak acids.

2.Weak base Anion Exchange

When the functional group attracted to

weak base is called week base anion. It performance better at low PH and

increase PH decreased it performance when PH more than 11

efficiency

SAB<WBA

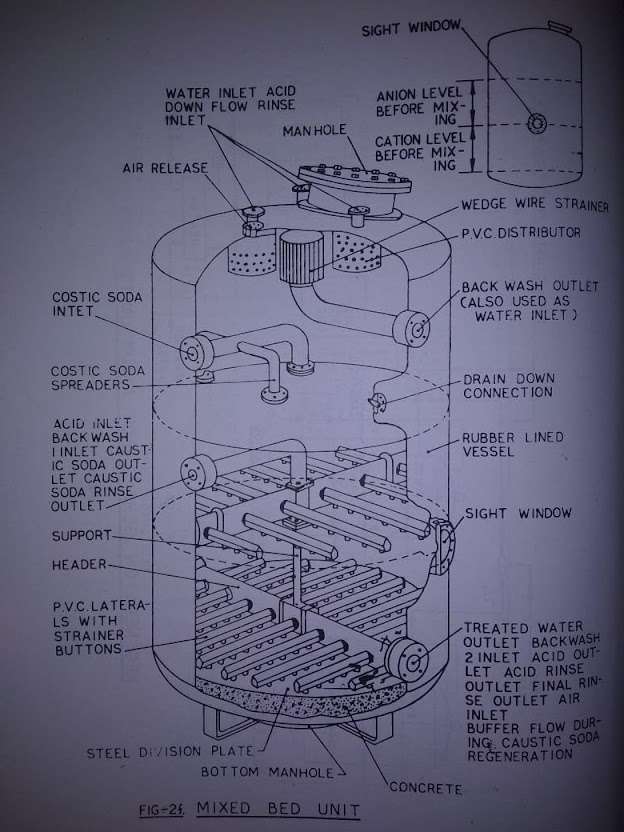

Mixed bed unit

This method

both anion and cation exchanger passing through water mixed bed unit is formed

and after mix bed unit DM water is made.

DEGASSIFIER

After

the cation exchanger the influent is acid and all the bicarbonate present in

water is converted to co2 , this co2 can

remove in degasser ,the capital cost of degasser is very less and running cost

also less. other wise co2 is remove in

anion exchanger. The theory of degasser based on following gas law.

DALTONS LAW

The total pressure exerted by a

mixture of several gases to the sum of the partial pressure of individual gas.

Again according to charls law the partial pressure of each gas is determined by

the amount of that gas in the mixture.

HENRYS

LAW

The solubility of the gas in water is directly proportional to the partial

pressure or that gas is contact with water.

X =

P/H

Where X= Amount of gas dissolved in water

P=Partial pressure of the gas in

contact with water

H= Constant at that

temperature